Conduct the challenge study Initially from the compression Procedure soon after initial machine location verified by QA.

“It is crucial that actions and scientific studies leading to process knowledge be documented.” – FDA

A different type of data validation is definitely the uniqueness Examine, which checks for the uniqueness of some facts entries.

Analyte quantitation might be carried out employing variables including peak peak, peak location, or ratio of peak heights/areas of analyte to The interior common.

Although a regular recipe would lay out substances and process, our in-depth recipe is additionally gonna set out anticipations for that devices we use and what our cake mix need to be like at many details through the entire baking process.

Whilst these experiments are not normally completed under cGMP disorders (like commercial production is), they're going to intently observe excellent science and can be diligently documented.

Results through the tests on the PPQ batches will confirm (with statistical importance) that merchandise from inside of a batch are dependable and satisfy the predefined merchandise good quality specifications. It may also validate regularity concerning batches.

Validation is an idea which has developed consistently considering that its first casual look in The us in 1978.

Knowledge validation is time intensive: As we presently pointed out, details validation is usually time intensive, especially for a lot more advanced databases and the ones that acquire info from unique sources. Nevertheless, it continues to be important for every undertaking to ensure fantastic benefits.

Process validation is definitely the Investigation of knowledge collected through the layout and manufacturing of products to make sure the process is consistently created as per the provided standard.

It is only via ongoing assured control of significant excellent attributes, that a pharmaceutical manufacturer can be particular that their medicines continue to get more info be suit for purpose, effective in use and Risk-free for people.

Ongoing assurance is gained through schedule generation the process continues to be in a condition get more info of Regulate.

Upkeep Dept. shall accountable for preventive upkeep and calibration of equipment and devices respectively.

The purpose of the stage is usually to style a process suited to program commercial producing which can consistently produce an item that satisfies nearly all its top quality attributes of actions connected with stage -1 shall be done, instructed by FDD.

Rick Moranis Then & Now!

Rick Moranis Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Alisan Porter Then & Now!

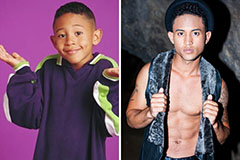

Alisan Porter Then & Now! Tahj Mowry Then & Now!

Tahj Mowry Then & Now! McKayla Maroney Then & Now!

McKayla Maroney Then & Now!